Trik Pamungkas: Integrasi Relay SIPROTEC5 ke SAS/Automation PACIS/DS Agile

30 November 2017, 13.36

Oleh: Ari Sulistiono di: DIGSI, Substation Automation

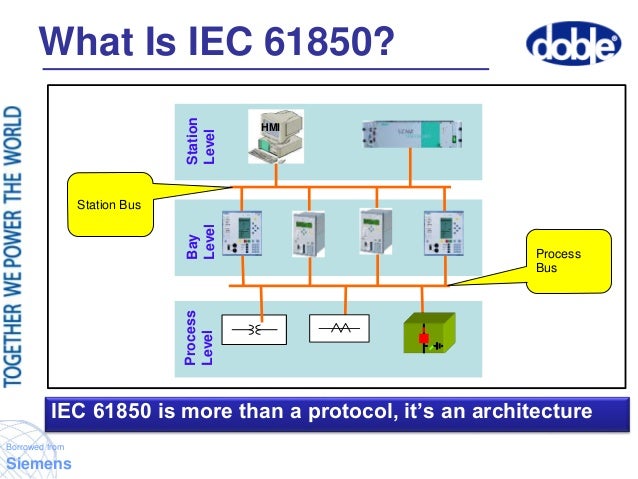

Dengan mempelajari metode ini, kami harapkan anda akan dengan cepat menguasai/mastering integrasi relay ber-protocol IEC61850. Setelah memahami yang ada pada video tutorial ini, integrasi merk lain pun menjadi sangat mudah dan lancar.

Langsung saja kita ikuti video tutorial dibawah ini:

Tags: DIGSI, Substation Automation

Video Tutorial Cara Integrasi Relay SIPROTEC dengan SAS/Automation Merk Lain

Idem, Di Jam 13.18

Oleh: Ari Sulistiono di: DIGSI, Substation Automation

Pada video tutorial kali ini kita akan kupas tuntas bagaimana caranya integrasi relay SIPROTEC dengan Substation Automation/Control System (selain Merk SIEMENS) via Protocol IEC 61850. Tutorial ini akan sangat berguna bagi anda yang berkecimpung dalam dunia Substation Automation atau anda bekerja di sistem integrator.

Pada video tutorial kali ini kita akan kupas tuntas bagaimana caranya integrasi relay SIPROTEC dengan Substation Automation/Control System (selain Merk SIEMENS) via Protocol IEC 61850. Tutorial ini akan sangat berguna bagi anda yang berkecimpung dalam dunia Substation Automation atau anda bekerja di sistem integrator.

Pada video pertama akan dijelaskan bagaimana membuat RCB dan Meng-Export configuration file/mapping telegram ke dalam bentuk FILE ICD atau CID atau IID. Dan pada video yang kedua akan dijelaskan bagaimana mengedit file ICD tersebut dalam format XML agar dapat diimpor oleh SAS selain merk SIEMENS.

Ok, langsung saja kita pada tutorial yang pertama:

Video tutorial berikutnya adalah bagaimana cara mengedit file CID tersebut agar dapat diimpor tanpa adanya error oleh SAS vendor lain (selain brand SIEMENS). Ok, langsung saja kita tonton tutorialnya sampai habis:

Tags: DIGSI, Substation Automation

How To Integrate SIPROTEC Relay/BCU to NARI Automation System

29 Desember 2016, 17.07

The advantages of using DIGSI 4.86 or higer version is more easier to creater report control block and in a single dataset may contains more than one report control block in a single click. Unlike in DIGSI 4.84 or lower version, each dataset is for one report control block.

But, in DIGSI 4.86 or higher version, the common problem during import SCL (CID or SCD) to another vendor HMI or Gateway is XML parse error. In this case, I’ll show you the thing that you have to do before importing CID file from SIPROTEC BCU or SIPROTEC Relays to NARI HMI and NARI RTU/Gateway successfully.

First, configure dataset and its contents (all signals which needed) and create the report (one report served one client such us HMI and Gateway). After finish the configuration, export the CID.

Second, before importing the CID to NARI HMI or NARI Gateway, you should edit the CID file and remove/delete unnecessary “Private” node in the CID file. You may use notepad++ or XML Notepad

In Notepad++, find and remove all section from <Private up to </Private>. And please don’t miss delete the other parts, otherwise the CID file will damaged or corrupt.

I suggest you to use XML Notepad to do this task, more safe and more easier for you. Download and install XML Notepad on your PC. Launch the XML Notepad and open the CID file.

Find all unnecessary Private folders

Push Delete button and search again using F3 button, Repeat deleting the Private folder until there’s no Private folder anymore.

Save the CID file then import it to the NARI HMI and NARI Gateway. You should have no more error during import the CID file. Thank God! Now all my SIPROTEC IED was successfully connected to NARI SAS.

If you still have any problem or question related to this subject, please don’t hesitate to contact me

Regards,

Ari Sulistiono | www.arisulistiono.com | Substation Automation Engineer | Siemens EM DG Promoter

How To Simulate SICAM PAS IEC-104 Connectivity to Master SCADA using ASE2000

22 Februari 2014, 21.22

Oleh: Ari Sulistiono di: SCADA, Substation Automation

Overview

Regarding our customers now is using Master SCADA with IEC 870-5-101 and 104 protocol. All of RTU or SAS projects must provide this protocol and successfully pass the interoperability test. The new project of Substation Automation System has to be proof that the system is able to communicate to master SCADA via IEC 870-5-101 protocol.

During Commissioning or SAT, often the customer request to test the IEC-101 or 104 of our SAS using a standard protocol tester such us ASE2000. Even this is very simple test, sometimes if someone not familiar with this protocol tester, then it’s almost impossible to perform the test and the SAS project will be fail. This document provides the basic configuration of ASE2000 to perform connectivity test of IEC-104 protocol of SICAM PAS.

Basic Setup

1 How To Simulate IEC-60870-104 Protocol (Master SCADA) in Protocol Tester ASE2000

ASE 2000 communication test set is a protocol tester or simulator that able to simulate many kind of protocol. This tool is powerful, except the software GUI is not user friendly and minimal user guide available. This document will explain the detailed how to simulate IEC 60870-104 protocol of SICAM PAS using ASE 2000 as the Master SCADA simulator.

Before start the configuration of SICAM PAS and ASE2000. First of all, we need to connect an Ethernet cable of SICAM PAS PC and ASE2000 PC to an Ethernet switch such us Ruggedcom. Also, ensure that SICAM PAS has been installed IEC-101 and IEC-104 protocol license on it. Set the IP Address of SICAM PAS PC and ASE2000 PC with same class IP Address.

ASE2000 Basic Configuration

Please follow this step:

1. Click menu File and Select Protocol to IEC 870-5-104. To perform this, ASE2000 software must have IEC-104 protocol license installed on it.

2. From Properties/Protocol Specific/Host, enter the IP address of the SICAM PAS or any Controlled Station (such us RTU or IED device to be controlled). Basically, IEC-104 protocol only needs IP Address to make connection.

3. From Properties/Protocol Specific/IEC 870-5-104, review timers and message count parameter specific to IEC 60870-5-104 protocols. The defaults should be OK for most systems, but can be changed if necessary, depend on master SCADA configuration which will be simulated in this test.

4. From Properties/Protocol Specific/Exchange Defaults, enter the Common Address of ASDU in the Comm Addr field. This is valid only for Controlled Devices with a single common address. The procedure for devices with multiple addresses is described later

Exchange Configuration

Normal Communication

Normal communication to IEC 870-5-104 devices requires use of the Simulate Master function. Except for the TESTFR message, Send Once or Send Continuously will not work correctly.

For Simulate Master, all exchanges to be transmitted must be configured prior to starting the simulation session. In the simplest case, successful communication to a Controlled Station can be established by sending only STARTDT ACT. This message allows the Controlled Station to transmit point information according to logic configured in the device.

No other exchanges need to be enabled. The ASE2000 automatically transmits housekeeping messages required to keep the link open and active.

To configure the STARTDT ACT and Interrogation exchanges:

- Double click the STARTDT ACT exchange to request the Edit Exchange Properties menu

- Set the Frequency to 0 seconds

- Check the Transmit exchange flag. Then Select OK

Repeat the above procedure for the Interrogation exchange

Other exchanges, such as command outputs, may be enabled to test other device features, but are not required. Other exchanges are enabled by following steps similar to those presented above. In addition:

The Frequency should probably be set to some value other than 0. A Frequency of 0 configures the ASE2000 to send the message once at startup. A non-zero Frequency causes the message to be sent periodically at the specified rate

Most other exchanges require additional configuration information such as an Information Object Address. Information specific to each exchange can be entered from the Edit Exchange Properties menu or from other menus accessible from there

or selecting File and Simulate Master.

If there’s any message response from SICAM PAS with “<--“ sign, it means that SICAM PAS is successfully connected to ASE2000 protocol tester.

SICAM PAS Configuration

The only requirement of connection between SICAM PAS to protocol tester or master SCADA is the IP Address of SICAM PAS PC shall be identical with protocol tester “Host Connection”.

We can use the Default setting of SICAM PAS. There’s no any setting which necessary to change here.

The ASDU Address also not necessary to change, we can change the ASDU if the configuration of master SCADA request this setting. By default setting, for IEC-104, only IP Address of SICAM PAS PC is possible to make connection and perform the test.

Open SICAM PAS – Operation, update system if required then we’ll see that SICAM PAS already connected to ASE2000 protocol tester via IEC-104 protocol.

TESTFR

A sole exception to the requirement to send an initial STARTDT ACT message exists for the Data Link layer TESTFR ACT exchange.

The TESTFR ACT exchange can be configured for transmission by following the same procedures as for any other exchange. Additionally, TESTFR ACT may be sent with Send Once or Send Continuously. These functions cannot be effectively used with any other message.

Multiple Common Addresses

An IEC 870-5-104 device can contain data points in more than one common address. Additional setup steps are required for communication to a multiple common address device. Specifically, item 3 in the Basic Setup section configures the ASE2000 for operation to a single Common Address. If this setup step is followed, then messages received from a different Common Address will be unrecognized by the ASE2000 and will eventually result in a network disconnect.

For communication to a Controlled Device with multiple Common Addresses (multiple SAS, eg. FAT with many SAS project):

From Properties/Protocol Specific/Exchange Defaults, make sure that the Common Address of ASDU (Comm Addr field) is set to an *. This is the default setting and instructs the ASE2000 to recognize messages from any Common Address

Enable STARTDT ACT as explained in the Normal Communication section

There are two options for enabling an Interrogation. The first option is to send an Interrogation to the broadcast address, 65535. The second option is to send a set of Interrogation messages, one to each Common Address. In either case, do not use the default Interrogation exchange. Create one new Interrogation exchange for each request to be transmitted. Only one new exchange is required to send a request to the broadcast address. Multiple new exchanges are required to send separate requests to each Common Address

To create a new Interrogation request, either:

Highlight the default Interrogation exchange, select Edit/Copy and Edit/Paste, or Select Edit/Create Exchange Template and select Interrogation

For each new Interrogation exchange:

Double click the exchange to request the Edit Exchange Properties menu. Set the Frequency to 0 seconds. Check the Transmit exchange flag. Enter the Common Address, either 65535 for the broadcast address or a specific device Common Address. Select OK

To configure other exchanges, such as commands, for transmission:

Create a new exchange for each command to be transmitted by following steps as explained in step 4. Configure the message for transmission as explained in step 5.

Download Article in PDF:

Tags: SCADA, Substation Automation

How To Simulate SICAM PAS IEC-101 Connectivity to Master SCADA using ASE2000

Idem, Di Jam 20.48

Oleh: Ari Sulistiono di: SCADA, Substation Automation

Overview

Regarding our customer now is using Master SCADA with IEC 870-5-101 and 104 protocol. All of RTU or SAS projects must provide this protocol and successfully pass the interoperability test. The new project of Substation Automation System has to be proof that the system is able to communicate to master SCADA via IEC 870-5-101 protocol.

During Commissioning or SAT, often the customer request to test the IEC-101 or 104 of our SAS using a standard protocol tester such us ASE2000. Even this is very simple test, sometimes if someone not familiar with this protocol tester, then it’s almost impossible to perform the test and the SAS project will be fail. This document provides the basic configuration of ASE2000 to perform connectivity test of IEC-101 protocol of SICAM PAS.

1. How To Simulate IEC-60870-101 Protocol (Master SCADA) in Protocol Tester ASE2000

ASE 2000 communication test set is a protocol tester or simulator that able to simulate many kind of protocol. This tool is powerful, except the software GUI is not user friendly and minimal user guide available. This document will explain the detailed how to simulate IEC 60870-101 protocol of SICAM PAS using ASE 2000 as the Master SCADA simulator.

Before start config SICAM PAS and ASE2000. First, connect RS232 of SICAM PAS PC to ASE2000 PC using a standard Null Modem cable, of course with cross serial TX-RX. Also, ensure that SICAM PAS has been installed IEC-101 and IEC-104 protocol license on it. If there’s RS416 due to redundant SICAM PAS server, in order to perform test we need to connect the RS232 cable to RS416 port which used as virtual COM Port.

Please follow this step:

1. Click properties - communication, in the channel tab make sure that you have right com port setting. In the Line tab chose constant as the carrier option, make sure the baud rate is same with SICAM PAS/RTU setting. This is COM Port of PC with ASE2000 installed on it.

2. Click Properties - Protocol Specific, In The Channel exchange defaults make sure that the DL address and Comm address' value is same with SICAM PAS setting. Check the Asynch and iec 870-5-101. Ensure that the values in that panel are same with SICAM PAS setting. Our customer recommended setting based on their master SCADA configuration: Data bits 8,1,Even and Length link is 2,2,3.

![clip_image002[4] clip_image002[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiXsyIy_Tr5Mcg1giHrDEu0BEcrkLCXpfJtxBG1nT4odU_wOVWbEqtB3qZBeEDf-kvgXa5Jf15zEOJUE_wvHAUvOrNHshgX24kmOjKCjscohdNhWbieDtw5JtHuNSI9IGMk-1SMCjgx7YDi/?imgmax=800)

3. go to exchange list, here are what you need to make connection in this protocol

- reset link (freq 0) (flag: display transmit)

- Access Demand (freq 0) (flag: display transmit)

- Interogeration (freq 0) (flag display transmit)

4. That's all. You may add more exchange list to pool by ASE2000 if needed.

Now Press to Simulate as Master SCADA. If SICAM PAS is successfully connected to ASE2000 via IEC-101 protocol, in line monitor will display response data with “<--“ sign. If connection is failed, the sign is “<==” with text “No Data …” or “Response Timeout”. The picture bellow is example of ASE2000 successfully connected to SICAM PAS.

SICAM PAS - Operation also show the connection status of IEC-101 protocol.

Sign : connected.

2. SICAM PAS CONFIGURATION

Set the baudrate to 1200, set the link address and ASDU address (eg. 170), COM Port used for test.

Set the length of link, ASDU & Object to 2, 2 & 3 as per customer or Master SCADA configuration

That’s all the necessary link configuration of IEC-101 of SICAM PAS

Download Article in PDF:

Tags: SCADA, Substation Automation

Teknik Dasar Setting & Konfigurasi AVR TRAFO (REG-DA)

2 Mei 2013, 22.22

Latar Belakang

![clip_image004[3] clip_image004[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjIvaIgb4UXvB6m8fNbuJzavO0aSbxLi_8Jvg2-OlPKPlS0hTkeRx8Glnhuv1UXp5iBzE9odtfvwCh-RPQv9MBxa7CUe0eXIRXv1Xm7gapNn9AMS28SZnoC0VsEFqR9US_BsDFPjYewP0Zt/?imgmax=800)

![clip_image002[3] clip_image002[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg4LPQgrk4CgnCmQs3wgXLwP3Fm9c2FhE-AV6ZKiVF91RmBYunzqu3tTueA2XmrnBAZDRzx4GCJVay8UBQzNLo93pJZkat4BgVmpDNV1lAyCcNpFHeiEcyX9Cl3EDhRJymfejxTj4X-xso7/?imgmax=800)

![clip_image006[3] clip_image006[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgacbLhdjJRQwCyLRxPRvbvCJOe5x5acV5HW2qQ1K4G9dRcgSs5xnD04pkLPkq8s5Bv5Cc_Km6YU5zqeEESrQINLBJxawBs7iAIG3uxiMh2sJmIc-BNdZMEWqww9ppgAq2k5R_7eZDfC0Bx/?imgmax=800)

Selain memonitor tegangan output TRAFO serta posisi TAP OLTC, AVR juga dapat memonitor secara real time berikut skema sistem proteksi TRIP TRAFO berdasar kondisi seperti: panas lebih (overheat), motor jammed, under/overvoltage, under/overcurrent, dll.

Di dalam dokumen ini akan dijabarkan cara setting AVR dasar agar AVR dapat menunjuk nilai actual value yang benar dan beroperasi dengan baik pada setting point 100% dengan besaran dan setting yang benar sesuai kondisi arus, tegangan dan temperatur aktual TRAFO. Untuk skema konfigurasi lanjutan (advance) akan dibahas di dokumentasi berikutnya.

sumber: arisulistiono.blogspot.com

Setting Dasar Rasio CT/VT pada AVR REGDA

Untuk melakukan setting AVR REGDA, kita dapat menggunakan software WinREG Setting of Parameters atau cukup langsung memasukkan nilai setting dengan keypad dari front panel REGDA.

Cara Setting CT/VT dengan Keypad dari Front Panel:

Tekan MENU delapan kali kemudian disana akan muncul tulisan CT/VT Configuration, tekan tombol disampingnya. Kemudian masukkan nilai Kni dan Knu pada REG-DA. Nilai setting Kni dan Knu bisa dihitung dengan kalkulator Excel yang terlampir pada dokumen ini.

Cara Setting CT/VT dengan Software WinReg:

Untuk setting dengan software WinREG Setting of Paremeters, kita membutuhkan kabel Null Modem Female-Female untuk koneksi port komunikasi komputer ke AVR REG-DA via COM1 AVR.

![clip_image023[3] clip_image023[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgnMHk9kw624kaYQkbfekuAspmASbszYCYDIIWeW57jvv2KR7d4TcNBxKxeekZ6ol4PCdZdqcsY2W0lPEwUv66e_Nx7ZJGdGx1YT2U2fgPZJJuRb2PbgwbdP4OgwRTctTfQzcOzY5EWfhqO/?imgmax=800)

Klik tombol Send to Device untuk mengirimkan nilai settingan CT/VT ratio ke AVR REG-DA.

Cara Setting Analog Input dengan Keypad dari Front Panel:

Analog input pada AVR digunakan sebagai pembacaan signal data analog seperti nilai temperatur oli ataupun kumparan Trafo, selain itu juga digunakan sebagai pembacaan nilai posisi Tap OLTC. Analog input dari Trafo biasanya dikirimkan ke AVR dalam bentuk signal 4~20mA, kemudian nilai ini dicacah dalam sebuah grafik linear, misal 0mA adalah 0 derajat celcius dan 20mA adalah 150 derajat celcius.

Agar AVR bisa menunjukkan nilai temperatur ataupun nilai posisi Tap yang benar, maka AVR harus disetting skalanya terlebih dahulu. Cara setting skala AVR REG-DA melalui front panel adalah sbb:

Tekan MENU, kemudian tekan F4 » MONITOR, selanjutnya adalah F5 » SETUP

Untuk memulai konfigurasi signal analog 4~20mA dari Trafo, pilih F5 » Analog-channels, disini REG-DA akan menampilkan nilai mA dari 6 channels yang ada. Untuk assign atau menyeting jenis signal masing-masing channelnya, tekan tombol segaris dengan channel tersebut. Misal F1 » Analog Inp. 1

Apabila sudah masuk ke layar Analog input yang dituju, misal Analog input 1, digambar digunakan sebagai indikasi temperatur Oli Trafo (OTI), maka tekan F1 » pilih tipe signal 64:OilTp-TR. Pilih OilTp-TR » untuk signal analog temperatur oil, pilih tipe iTapPos » untuk signal analog dari Posisi Tap OLTC, pilih iWindTp-TR » untuk signal analog winding temperatur

Kemudian gunakan file Excel disini untuk menghitung nilai P0-X & Y serta P2-X dan Y. Metode perhitungan atau Parameter Selection biasanya menggunakan 02:P0P2. Untuk transmitter termocouple yang umum digunakan biasanya skalanya adalah 0 derajat di 4mA dan 150 derajat di 20mA. Maka nilai yang harus dimasukkan disana adalah:

- P0-X = 0 DegC

- P0-Y = 0.2

- P2-X = 150 DegC

- P2-Y = 1

Gunakan F1 dan F2 untuk menaikan nilai skala yang dikehendaki dan tombol F4 dan F5 untuk menurunkan nilai skala.

Apabila nilai skala yang diperlukan sudah dimasukan semua, tekan ENTER dan gunakan tombol panah ◄► untuk menggeser model pembacaan dari mA ke DegC. Maka akan terlihat disini bahwa nilai temperatur telah terbaca. SELAMAT!

Lalu bagaimana dengan Tap Changer Position? Pada OLTC, nilai posisi TAP dari 1 s/d 18 (OLTC Merk MR yg umum dipakai) biasanya nilai tersebut dikirim via kontak NO untuk indikasi tipe lampu, kontak BCD untuk indikasi decoder digital, dan ada juga yang menggunakan signal analog 4~20mA.

Untuk menyeting signal posisi Tap 1-18 dengan input 4-20mA, maka nilai settingnya adalah sbb:

- P0-X = 1

- P0-Y = 0.2

- P2-X = 18

- P2-Y = 1

Cara Setting Analog Input dengan Software WinREG:

Buka software WinREG, kemudian pilih tipe AVR REG-D, setelah itu klik Tab Analog I/O.

![clip_image054[3] clip_image054[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjT27zFZu4Qp0VG_XVLDmus1ZdhpvaY1UAWYmJQwWKkHrqyMKbZe7rZZiYNZvqtqM8EbJXFsh-ne91hAiVnMDI9bcqOlYlN7XNmWCmpq43CR9UJqbujWZ47vThAEoiwzVgcSaEdPFl9c05P/?imgmax=800)

pada bagian Function dan pilih OilTp-TR » untuk signal analog temperatur oil, pilih tipe iTapPos » untuk signal analog dari Posisi Tap OLTC, pilih iWindTp-TR » untuk signal analog winding temperatur.

Kemudian masukkan nilai skala yang digunakan, jika menggunakan software WinReg anda tidak perlu menghitung manual dengan bantuan kalkulator Excel terlampir. Cukup memasukan nilai batas atas dan batas bawah saja. Misal: pada saat 4mA nilai Tap adalah 1 dan pada saat 20mA nilai Tap adalah 18.

Klik tombol Send to Device untuk mengirimkan nilai settingan CT/VT ratio ke AVR REG-DA. SELESAI!

Saat pengujian signal 4~20mA, gunakan file Excel terlampir untuk memverifikasi nilai yang ditampilkan oleh AVR, seharusnya nilainya sama dengan nilai di kalkukasi Excel.

sumber: arisulistiono.blogspot.com

Interfacing HMI to AVR REG-DA via Protocol 61850

List Logical Node IEC61850 AVR REG-DA:

Daftar logical node ini mungkin diperlukan untuk integrasi AVR REG-DA dengan Software Automation via IEC61850 protocol:

- Auto-Manual Command+Status » E07AVR1A/ATCC1/Auto

- Oil Temp Indicator Value (analog input-DegC) » E07AVR1A/ATCC1/TmpOilTr

- Winding Temp Indicator Value (analog input-DegC) » E07AVR1A/ATCC1/TmpWind

- AVR In Local Position status » E07AVR1A/ATCC1/Loc

- Counter OLTC Value » E07AVR1A/ATCC1/TotNTapChg

- Tap Position Value + command (via Analog/BCD) » E07AVR1A/ATCC1/TapChg

- Control Raise Tap » E07AVR1A/ATCC1/TapChgUp

- Control Lower Tap » E07AVR1A/ATCC1/TapChgDown

- Status Binary Input AVR » E07AVR1A/GGIO1/Ind1 (Ind1...Ind16)

- Semoga Bermanfaat –

sumber: arisulistiono.blogspot.com

![clip_image002[6] clip_image002[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhMouYhVedSjzQdn7Tuk0FDTaR_blI5_jc5r5MAlABCjiyKXhegIS9bRbME1YyfsF00l6hGRjm6KtdwdPJyV2bouQ9qYe0rWnTffRz0_BSS-cWh9pDWIBBKiPTKSfsld2ytuObvjVhNq3Np/?imgmax=800)

![clip_image002[8] clip_image002[8]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjt9A8tsYk2BQAxdRsn-akD4sioTQonRFoRfrpFV9P852QiDlTZfzHQSfpr8DWXZupZXVLs0RiRt_c9RILtoxPDyoL65HHbCFdSNaQxvnWHtkzocEur18ppFuhaHac4M73-Sg13C7Ha36jU/?imgmax=800)

![clip_image004[4] clip_image004[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhWrRPcc6b1ZTDvMf6L2MFkCEzsoSFJVsbqNHcqAFLJyVsfWLWvVHlBVQvoYngGMnJ9rhMadIXhvJONw4eZ2nlSCMrzQe-p6scluKKQHG-KyL1uDaYLwOj4mgYGrkehCoNMHSTeuPsn1sXU/?imgmax=800)

![clip_image030[3] clip_image030[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEh0wT1IjDhfVFQRSodlgxxRdEp7WFYfEFoj3i4E-esV11ow4rdGx0q6qqtYjAn8q0M-ATOHr04mO6wyAu-5_VV2jPWye7rK96CDCY378SkTU3Rrl7hoolpWiqhEM_RAP5rz_SDXRGidAXyM/?imgmax=800)

![clip_image032[3] clip_image032[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjeOh0G0D09ll3_lJrhccjoE9kJ4W6yKuD1HdgmPVXZKkhskmTbqiCVWV5fzuRMjOYaKloX49OmevMI2c7MZjy36JJP4gfrNaNBajD8BsgoeykVYmyZ7ZIfqKNgtk2s4UIxUXmtXK6gRqUJ/?imgmax=800)

![clip_image034[3] clip_image034[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgUsymV3J6zBA1ByTvEFIQmf8Myvn3eSAGbKAsY14CFZstM7A1jPSwKLhUHQ_A5hKS8jrpqtn_E3YwHQk9ZeWMbCRwEqPtlm1VXeNxVWkj-cUVp6QPncHpBuV3Mlfov336d_h_YlAhzKBQS/?imgmax=800)

![clip_image036[3] clip_image036[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgiYxvDL_xf7nz-bcnFJvKEF7NhMVyYDPCq18cNVBkrYR2_8_sSQxvcCnJX3gm-aws5F21oG25JvjqSDkLdeQ3ld2NYGVlyaRCs7PiRy1HW59IDM6iV2BHOJvkwmoM_OVNtJPApAnFFr-CZ/?imgmax=800)

![clip_image038[3] clip_image038[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiSVFzgectVEPatH_giV51dgwnhxPFGkHqq6bj-IC6DLojZo7iXw_bFEMXelovHfPh4Q6tq9tXxri6cPgAjt0D5tfYvCaoxxXIbkxRSWhUTT80S0-BwQE-8G6ANnesowoyTa3KZwsM3ya0o/?imgmax=800)

![clip_image040[3] clip_image040[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhKGNgaIxWZuJXl85N4L9kj1Z-ClHXRrx8oDeYwNcu3IxZQW08O5mbvBD99-FWqPDsoo4AfQUaPI7XY9OdJWm4W3sy-CxSNaU9WTV10hbJEESKe0y9lao8zPsWmrbMOfsfd7aJ6P376fqgX/?imgmax=800)

![clip_image042[3] clip_image042[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgKxOczFxwXSebewy4vDw12HJZ_BwqwPR7a9tOXSftWFOHMMVnzj6HeKrmgxixX2NQf9Oyjjb9sP8EAe3iTFRByDrtkl-nluOx1_yinjnWFfdcdFXIgoZe4eKWywzm4itV11dMxeTzq8FyN/?imgmax=800)

![clip_image044[3] clip_image044[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi7g2q9klh4s4JoKDcYW3FxvkAZWuM4S33P7a4YvgzQFKInJ_iBf_ZTYObh4CB1GNXffZ5d7CO1hxpUrRY_sdT9KL8az3NXpFRWA9ZjBJmxJATEqsE5-riESrIsZbTbFdI9xd2pknWlpaVC/?imgmax=800)

![clip_image046[3] clip_image046[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgn7tVJnPcNUSvZylaPBgqqx8VlzqzWqeJuVSR8_iB2k9dn_JV5cGk8yCtAjcRRo07kWZE-l85Qr44PeqjdoAcQ5AhOUN9ThfVVpzCQeYinEPwxVoNMU4HSOw1YgeU9Gsb0teuoX68CWxjW/?imgmax=800)

![clip_image048[3] clip_image048[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEii-vNR-Anhoxx1WCl5ohOJ3JweHN_bmnEtQCFgijlVRqzNhiHl5Kk28bcqywWwLZ6kzNLbQzTbQc-YwRdPqLldYxI3DhGI70364VFmgQtnd5r2-0dlAJtFFkyrRaeF5JVUHMxa6WFc8KxO/?imgmax=800)

![clip_image050[3] clip_image050[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiEH0CZiU-lVQvg5nJnkFLYbnql-mJ4Nv_66DEVoPSBANFB0SUZRv5mmbYPPAC6sdW8SohFHpomiiPJ18Kni0LEusYniUg7mf7luDslTfKVjkinIhxN-020vZy4denCo-eEKbg-kix_FS5P/?imgmax=800)

![clip_image052[3] clip_image052[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhzsAa1mMtOaJor2honf34P4aSIMpY_qrP7PZZWzfKNqMt54gBjfDVZw2JXRGYYdXbFyv4AMHr2YOxg3jq_usHWo1ZmgccGTgAYLpBgOcryGsNSzI37sQDYYXTEjMZNqV9CP3kVL0gmupOM/?imgmax=800)

![clip_image056[3] clip_image056[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi6oB0OyjYYqfUCtar1KyEBJJukISL9BIF8pg7qd6GsLpV4zDEyB3mP9JkJ7jNjL5gfARci5IdbE6_aiVURoshm4LHvgMfBPJdy2TykrK-iRHOEa31fjK1LYlq9WjT8mSiVCriV8-cfUmkz/?imgmax=800)

![clip_image060[3] clip_image060[3]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEirkNvd_0aSHtbrFTixH-WwHC1bWK3Wc-kiTCvEpjS96VfCe4A1o7saovQ1TO_R_zz4UGb8PlNJh0e3rarouVT78xzRhLH1ubW6xS6C0Kc0inebNAdCl6CVJqj4lWliEQW3cCgu8ik76RN7/?imgmax=800)

View

View